Title 51

PUBLIC HEALTH―SANITARY CODE

Part XIII. Sewage Disposal

Chapter 1. General

[formerly Chapter 13 Subpart A]

§101. Definitions

[formerly paragraph 13:001]

A. As used in this Part, the terms defined in this

Chapter supplement any definitions which may be set

forth in law and shall have the following meanings

and/or applications, unless the context or use thereof

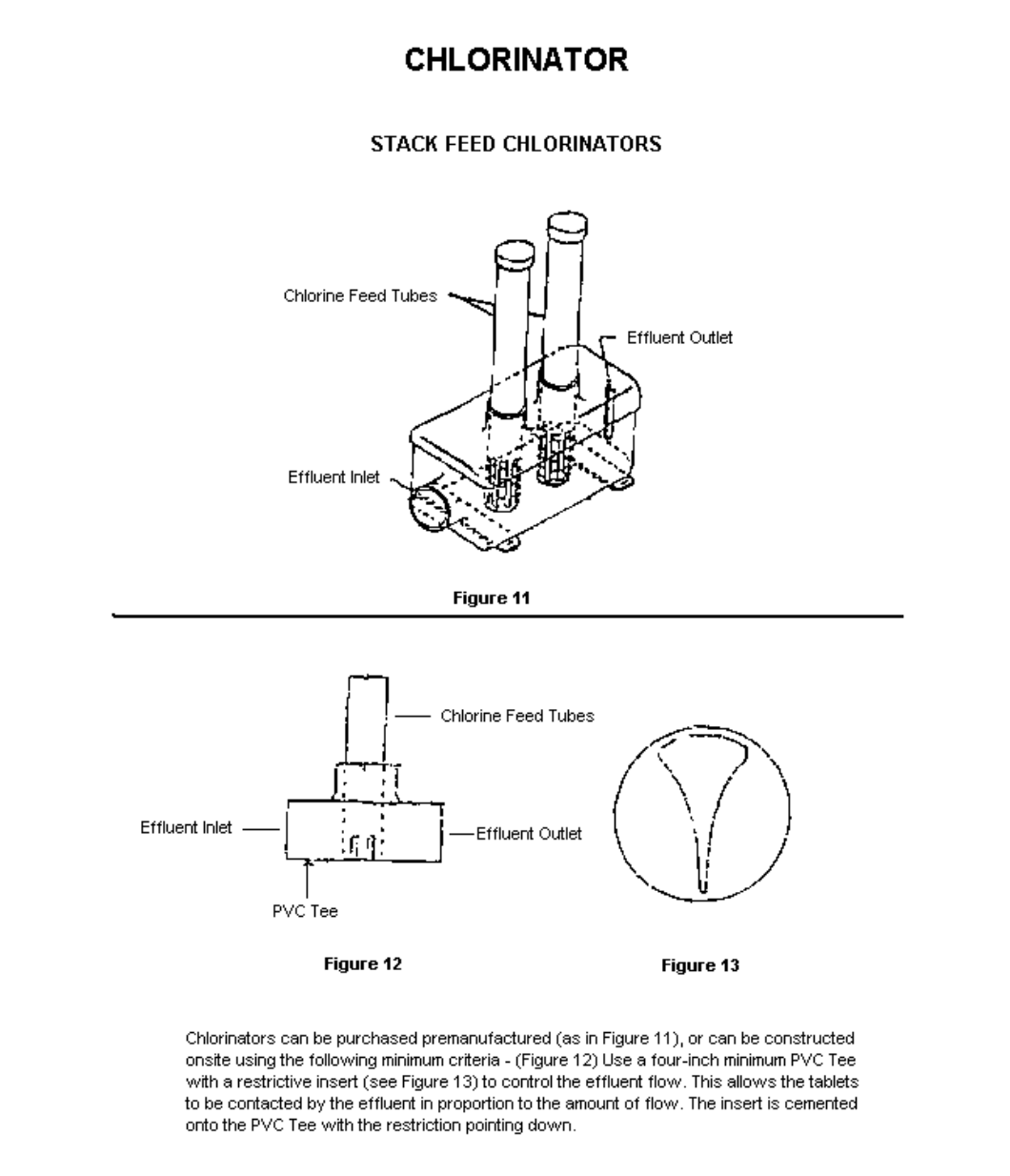

clearly indicates otherwise, or more explicit definitions

and/or applications are referenced. Terms not defined or

referenced herein shall have the meanings as defined in

the other Parts of the sanitary code of the state of

Louisiana. In any instance where a term defined herein is

also defined in one or more other Parts of this Code, the

definition contained in this Part shall be given preference

as it pertains to sewage disposal.

Commercial Treatment Facility (designed in

accordance with §503)―any treatment facility which is

required by the state health officer whenever the use of

an individual sewerage system is unfeasible or not

authorized.

Community Sewerage System―any sewerage system

which serves multiple connections and consists of a

collection and/or pumping/transport system and

treatment facility.

Conventional Septic Tank System―a septic tank

system which consists of a septic tank(s) followed by a

subsurface absorption field.

Facility or Facilities―any or all of the apparatus and

appurtenances associated with a sanitary sewage

treatment system, element, or process.

Gravelless Pipe―a proprietary device which may be

used in lieu of conventional subsurface absorption field

materials when approved by the state health officer.

Individual Mechanical Plant―a treatment facility

which provides primary and secondary treatment of

sanitary sewage by use of aerobic bacterial action which

is sustained by mechanical means.

Individual Sewerage System―any system of piping

(excluding the building drain), and/or collection and/or

transport system which serves one or more connections,

and/or pumping facility, and treatment facility, all located

on the property where the sanitary sewage

originates; and which utilizes the individual

sewerage system technology which is set forth in

Chapter 7 Subchapter B of this Part, or a commercial

treatment facility which is specifically authorized for

use by the state health officer.

Limited Use Sewerage System―a sewerage

system which may be authorized by the state health

officer for installation or use for a structure or

dwelling which is occupied less than four days in a

week, and the use of which generates less than 100

GPD of sanitary sewage.

Manufacturer―a person who engages in the

business or practice of constructing individual

mechanical sewerage treatment systems, and who

is responsible for having the system evaluated in

compliance with §725.D of this Part.

Person―any natural person, partnership,

corporation, association, governmental subdivision,

receiver, tutor, curator, executor, administrator,

fiduciary, or representative of another person, or

public or private organization of any character.

Premises―any structure or dwelling of any

construction whatsoever in which a person may live,

work, or congregate.

Sanitary Sewage―any and all human waste

and/or domestic waste, the disposal of which

requires a sewerage system approved or authorized

by the state health officer. Sanitary sewage may

include its conveying liquid and/or any other liquid

or solid material which may be present therein.

Secondary Treatment Standard―a sewage

effluent water quality standard which prescribes a

maximum 30-day average concentration of

biochemical oxygen demand (5-day basis) of 30

milligrams per liter (mg/l), and a maximum daily

concentration of biochemical oxygen demand (5-day

basis) of 45 mg/l. The 30-day average concentration

is an arithmetic mean of the values for all effluent

samples collected in the sampling period. The

analyses to be performed for the purpose of

determining compliance with these effluent

limitations and standards shall be in accordance with the

eighteenth edition of the "Standard Methods for the

Examination of Water and Wastewater," available from

the American Public Health Association 1015 Eighteenth

Street NW, Washington, D.C. 20036, except where

otherwise specified.

Septic Tank System―an individual sewerage system

which consists of a septic tank(s) followed by a process

which treats and disposes of the septic tank effluent.

Sewerage System―any system of piping (excluding

the building drain and building sewer) and/or collection

and/or transport system and/or pumping facility and/or

treatment facility, all for the purpose of collecting,

transporting, pumping, treating and/or disposing of

sanitary sewage.

Subdivision for the purpose of these regulations―

a. the division, or the process or results thereof,

of any land into two or more lots, tracts, parcels, or

plots, any one of which has an area of less than 3 acres;

or

b. the re-subdivision of land heretofore divided

into lots, tracts, sites or parcels; provided, however, that

minimum lot size restrictions presented in §511.B shall

not apply to:

i. a subdivision legally established and

recorded prior to July 28, 1967; or

ii. a small parcel of land sold to or exchanged

between adjoining property owners, provided that such

a sale or exchange does not create additional lots.

c. Note: For the purpose of these regulations, the

requirements for wetlands might be more stringent.

Sub-Manufacturer―a person or entity authorized by

a licensed manufacturer to construct, or assemble

individual sewerage systems, or any portion thereof.

Trailer Coach―any of the various forms of structures

which are equipped, or capable of being equipped, with

wheels, including, but not limited to, travel trailers, truck

coaches or campers, mobile homes, trailers, and/or tent

campers, whether capable of moving under its own

power or not, and where a person or persons may live,

work, or congregate.

Trailer Park―any lot, tract, parcel or plot of land

upon which more than one trailer coach is or may be

located, and where trailer coach spaces are rented or

leased.

AUTHORITY NOTE: The first source of authority for

promulgation of the sanitary code is in R.S. 36:258(B), with

more particular provisions found in Chapters 1 and 4 of Title 40

of the Louisiana Revised Statutes. This Part is Promulgated in

accordance with R.S. 40:4(A)(6) and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of

Health and Hospitals, Office of Public Health, LR 28:1343 (June

2002).

Chapter 3. General Requirements for

Sewerage Disposal

[formerly Chapter 13 Subpart B]

§301. Plumbing Fixtures

[formerly paragraph 13:002]

A. All premises shall be provided with plumbing

fixtures as prescribed in Part XIV of this Code. Such

plumbing fixtures shall be connected to a

community sewerage system whenever feasible or

to an individual sewerage system which is

specifically approved for the premises by the state

health officer after it is determined that connection

to a community sewerage system is unfeasible and

that the installation and operation of an individual

sewerage system is not likely to create a nuisance or

a public health hazard.

AUTHORITY NOTE: Promulgated in accordance with R.S.

40:4(A)(6) and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of

Health and Hospitals, Office of Public Health, LR 28:1344 (June

2002).

§303. Responsible Parties

[formerly paragraph 13:003]

A. A person who owns, operates, manages, or

otherwise controls any premises, shall provide for

sewage disposal in a manner which is in compliance

with this Code.

AUTHORITY NOTE: Promulgated in accordance with R.S.

40:4(A)(6) and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of

Health and Hospitals, Office of Public Health, LR 28:1344 (June

2002).

§305. Discharges

[formerly paragraph 13:004-1]

A. A person shall not directly or indirectly

discharge, or allow to be discharged, the contents or

effluent from any plumbing fixtures, vault, privy,

portable toilet, or septic tank, into any road, street,

gutter, ditch, water course, body of water, or onto

the surface of the ground.

AUTHORITY NOTE: Promulgated in accordance with R.S.

40:4(A)(6) and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1344 (June 2002).

§307. Installation

[formerly paragraph 13:004-2]

A. No component part of a sewerage system shall be

installed wherever contamination of a ground water

supply may occur. The location of any sewerage facility

shall not conflict with the placement requirements for a

water well which are set forth in Part XII of this Code.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1344 (June 2002).

§309. Previous Permits

[formerly paragraph 13:005]

A. Any permits issued, or approval of plans and

specifications granted prior to the effective date of the

1998 revisions of this Part shall remain in effect as it

relates to the design of the sewerage system, unless the

state health officer determines there exists a need for

revision of such permits or approvals.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1344 (June 2002).

Chapter 5. Community Sewerage

Systems

[formerly Chapter 13 Subpart C]

§501. Permits

[formerly paragraph 13:006]

A. A person shall not construct or operate a

community sewerage system, or make a modification of

an existing system which changes the system's capacity,

effluent quality, point of discharge, hydraulic or

contaminant loadings, or operation of the component

units of the system without having first obtained a

permit from the state health officer. No community

sewerage system shall be constructed, or modified to the

extent mentioned above, except in accordance with

plans and specifications for installation which have been

approved as a part of a permit issued by the state health

officer prior to the start of construction or modification.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1344 (June 2002).

§503. Plans

[formerly paragraph 13:007]

A. Detailed plans and specifications for the

construction or modification of a community sewerage

system for which a permit is requested shall be

submitted by the person who is the owner, his legal

agent or who has responsible charge of the

facilities. The review and approval of plans and

specifications submitted for issuance of a permit

will be made in accordance with the design

standards presented in "Recommended Standards

for Sewage Works," 1990 Edition, promulgated by

the Great Lakes and Upper Mississippi River Board

of State Sanitary Engineers and available from

Health Education Service, P.O. Box 7126, Albany,

New York 12224. Proposals which deviate

significantly from the standards must be submitted

to the state health officer with supporting

documentation.

AUTHORITY NOTE: Promulgated in accordance with R.S.

40:4(A)(6) and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of

Health and Hospitals, Office of Public Health, LR 28:1344 (June

2002).

§505. Operation and Maintenance

[formerly paragraph 13:008-1]

A. All component facilities of a community

sewerage system shall, at all times, be maintained in

the same configuration as permitted, in working

order and operated efficiently to minimize upsets,

discharges of excessive pollutants, bypassing of

discharges from the system, and health hazards and

nuisances. Operator staffing and training, laboratory

and process controls, maintenance during normal

periods of equipment downtime, backup

equipment, and spare parts shall be provided as

needed to maintain continuous compliance with the

effluent limitations and standards established for

the facility by the state health officer and to avoid

any bypass or any overflow from the system.

B. [Formerly paragraph 13:008-2] Community

sewerage systems shall be operated and maintained

so as to consistently produce effluent water quality

meeting the minimum requirements of the

secondary treatment standard. Additional effluent

standards may be established by the state health

officer as needed based upon downstream uses of

receiving waters.

C. [Formerly paragraph 13:008-3] The bypass of

any raw or partially treated sewage from a

community sewerage system is prohibited, except

where unavoidable to prevent a potential threat to

Public Health and Safety or severe property

damage, and where no feasible alternatives to

bypass exist. The use of alternatives to bypassing,

such as auxiliary treatment facilities, retention of

untreated wastes, maintenance during normal periods of

equipment downtime, or installation of adequate backup

equipment shall be utilized to the maximum extent

feasible to avoid bypassing.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1345 (June 2002).

§507. Records

[formerly paragraph 13:009]

A. By request, copies of reports and suitable daily

analyses and records of daily operations shall be

submitted monthly to the state health officer.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1345 (June 2002).

§509. Land Application

[formerly paragraph 13:010]

A. No sewage sludge, or sewage treatment effluent

shall be applied to land for treatment, disposal, irrigation

or other purposes without a permit from the state health

officer. The Louisiana Department of Environmental

Quality should also be contacted regarding other

approvals or permits required by that agency for land

application projects.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1345 (June 2002).

§511. General Requirements

[formerly paragraph 13:011-1]

A. Connections to Community Sewerage Systems.

Where an established community sewerage system

(either public or private) is available, and there is ample

water supply, all plumbing fixtures within any structure

shall be connected to such community sewerage system.

Determination by the state health officer of the

availability of a community sewerage system shall take

into consideration, among other aspects, the separation

(both horizontal and vertical) of the structure in question

and the sewer main or lateral, political or geographic or

legally created boundaries, and the available capacity of

the sewer system.

B. [Formerly paragraph 13:011-2] Community

Sewerage System Required. Community sewerage

systems shall be provided for all new subdivisions and

developments where lots are sold or leased. The

developer/owner shall be responsible for the provision

of adequate sewage treatment and disposal. The use of

individual sewerage systems in lieu of a community

sewerage system may be authorized and will be

considered under the following circumstances.

1. In subdivisions comprised of less than 125

lots, when the developer submits a comprehensive

drainage plan as well as a proposal for restrictive

covenants which detail requirements for perpetual

maintenance of drainage. This requirement shall

apply for all new subdivisions and developments.

2. When the total anticipated design flow to

the sewerage system does not exceed 1,500 gpd,

and where no food service is involved as per

§1301.A.2.

3. On large lots, where an area of one acre or

more is involved, having a minimum frontage of 125

feet.

4. The installation would be located on a lot,

plot or site which has a minimum area of 22,500

square feet, and a minimum frontage of 125 feet.

5. For subdivisions when each and all lots have

a minimum area of at least 22,500 square feet and a

minimum frontage of 125 feet, except that the 125

foot frontage requirement may be waived for up to

15 percent of the total number of lots in the

development if:

a. minimum frontage on each lot in question

is not less than 60 feet, and;

b. the width of each lot in question is at

least 125 feet.

6. For parishes in which the parish governing

authority has enacted and enforces a formal sewage

permitting system (requiring approval of individual

sewage disposal systems by the state health officer

prior to issuance of any parish permits) and when

the lots or sites in question meet any of the

following criteria:

a. minimum area of 22,500 square feet and

a minimum frontage of 80 feet;

b. minimum area of 16,000 square feet and

a minimum frontage of 80 feet where an approved

individual mechanical plant is to be utilized;

c. minimum area of 12,000 square feet and

a minimum frontage of 60 feet where an approved

individual mechanical plant is utilized and is

followed by 50 feet of modified absorption field

(see Chapter 7 Subchapter B, §733.A).

7. Where lots of "record" (i.e., lots created by

formal subdivision prior to July 28, 1967) are combined

(in accord with the definition of a subdivision) to create a

new, larger, single lot, and no re-subdivision of the

property is involved. On July 20, 2002 and thereafter, in

no case shall the newly created lots have less than 50

feet of frontage or be less than 5,000 square feet in area.

8. For single lots or sites, regardless of size,

remaining in substantially developed previously

established subdivisions, when, in the opinion of the

state health officer, a hazard to the public health will not

result.

9. For single lots or sites, regardless of size, when

the installation of an individual sewerage system is

proposed in order to renovate or replace a pre-existing

sewerage system. Such installation may be allowed

when, in the opinion of the state health officer, a public

health hazard or nuisance will not result. This provision

shall apply to the renovation or replacement of pre-

existing systems only and shall not be utilized to

circumvent other requirements, particularly those

relative to minimum lot size for new residences and

subdivision development, of this code.

C. [Formerly paragraph 13:011-3] Effective October

20, 2000, this rule applies to new individual sewerage

system installations, upgrades and/or modifications to

existing systems required as a result of an investigation

by the Office of Public Health (OPH) into an allegation

that a violation of Part XIII of the Louisiana sanitary code

has occurred or is occurring, and has the potential for

causing harm or creating a nuisance to the general public

(R.S. 40:1154). Such individual sewerage systems with a

capacity up to and including 1,500 gpd, that produce

treated effluent, and which, by design, do not

significantly reduce the amount of off-site effluent, shall

be followed by an effluent reduction system constructed

as described in Chapter 7 Subchapter B, §§731 and 733

of this Part.

D. [Formerly paragraph 13:011-4] The state health

officer may consider for approval, on an individual basis,

proposals for developments that are of a unique nature,

such as a development over water, or irregular

configuration, where individual sewage disposal is

proposed, where the development, by its very nature

(e.g., where commonly or jointly owned property is

involved), is clearly not addressed by the current

considerations of this Code.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6),

R.S. 40:5(9)(20), and R.S. 40:1154(A).

HISTORICAL NOTE: Promulgated by the Department of

Health and Hospitals, Office of Public Health, LR 28:1345 (June

2002), amended LR 28:1591 (July 2002).

Chapter 7. Individual Sewerage

Systems

[formerly Chapter 13 Subpart D]

Subchapter A. General Requirements

§701. Permits

[formerly paragraph 13:012-1]

A. A person shall not install, cause to be

installed, alter subsequent to installation, or operate

an individual sewerage system of any kind without

first having obtained a permit from the state health

officer. No person shall install, cause to be installed,

or alter subsequent to installation an individual

sewerage system of any kind except in accordance

with the plans and specifications for the installation

which have been approved as a part of a permit

issued by the state health officer. Such permits shall

be issued in a two-stage process in accordance with

§701.B and C.

B. [Formerly paragraph 13:012-2] Upon receipt

of a request for such permit, and approval of plans

and specifications for the proposed individual

sewerage system (which shall accompany any such

request for permit), a temporary permit, authorizing

the installation of said system, may be issued. Any

such temporary permit shall be in writing and shall

not be issued until, with respect to the property and

its surroundings, the state health officer has

determined that connection to a community-type

sewerage system is not feasible, and that the

condition of the soil, drainage patterns, the lot

size/dimensions, and other related factors are such

that the construction and use of properly designed

individual sewerage facilities are not likely to create

a nuisance or public health hazard.

C. [Formerly paragraph 13:012-3] A final permit

approving the installation, shall be issued only upon

verification that the individual sewerage system has

been installed in compliance with this code. The

verification of such installation shall be determined

by means of an on-site inspection conducted by a

representative of the state health officer and/or in

the form of a completed "Certification by Installer"

form submitted to the state health officer by the

licensed installer. The installer shall notify the

appropriate local Parish Health Unit prior to the

installation of an individual sewerage system. The

sanitarian shall not issue final approval for this system

unless he/she has received a completed and signed

certification by installer form. The certification by

installer shall be submitted to the state health officer

within 15 days after completion of the installation. A

final permit shall be issued and provided to the

owner/occupant of the premises to be served by the

individual sewerage system.

D. [Formerly paragraph 13:012-4] If a consumer

currently owns, is contemplating purchasing and having

installed, or is an installer of Individual Mechanical

Sewage Treatment Plants, that consumer should be

made aware that:

1. it has become apparent that the electrical

components of Individual Mechanical Sewage Treatment

Plants which require connection to a source of electricity

may not be properly connected to that electrical source

in some cases. Specifically, mechanical sewage treatment

plants, using electrical power may require a properly

installed Ground Fault Current Interrupter (GFCI);

2. the Office of Public Health has specific statutory

authority and mandates to protect the public health

from the improper treatment and disposal of sewage.

This office will offer the public consultation with regard

to the appropriate sewage treatment system that should

be used in a specific application, considering system

design for properly treating sewage, sizing for the

number of people using the system, location of the

system, and other health considerations, as necessary.

However, the Office of Public Health does not have the

authority to inspect or approve electrical connections,

are not qualified in the area of such electrical

connections and will not assume responsibility for such

electrical safety considerations;

3. accordingly, proper electrical connections must

be made to the air pump/blower and/or any other

electrical components that are integral parts of an

individual mechanical sewage treatment plant, and that

a qualified electrician should perform or examine the

installation(s) for appropriate wiring and installation, as

well as the connection to the ground fault current

interrupter.

E. [Formerly paragraph 13:012-5] Permits for the

installation of individual sewerage systems shall not be

issued for lots within a formal subdivision unless an

official recorded plat/property survey has been filed with

and subsequently approved for use of individual

sewerage systems by the Office of Public Health.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of

Health and Hospitals, Office of Public Health, LR 28:1346 (June

2002).

§703. Plans

[formerly paragraph 13:013-1]

A. The review and approval of plans and

specifications for the proposed individual sewerage

system shall be made in accordance with the

"Regulations Controlling the Design and

Construction of Individual Sewage Systems" (See

Chapter 7, Subchapter B).

B. [Formerly paragraph 13:013-2] Individual

sewerage systems, other than conventional septic

tank systems, i.e., septic tanks followed by a

subsurface disposal system, including those facilities

built in conflict with the state of Louisiana sanitary

code, shall comply with all provisions of the

Louisiana Department of Environmental Quality

Wastewater Discharge Permit. The Louisiana

Department of Environmental Quality should be

contacted for information regarding wastewater

discharge permits. The state health officer may

establish other limitations or standards, as needed,

in consideration of the water quality of affected

surface water bodies and groundwaters.

AUTHORITY NOTE: Promulgated in accordance with R.S.

40:4(A)(6) and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of

Health and Hospitals, Office of Public Health, LR 28:1347 (June

2002).

§705. Installation of Individual Sewerage Systems

[formerly paragraph 13:014-1]

A. A person who wishes to engage in the

business of installing or providing maintenance of

individual sewerage systems shall obtain, in

accordance with the procedures set forth in §737 of

this Part, a license for such activity prior to making

any such installations or providing maintenance.

Such a license shall not be required, however, for an

individual wishing to install an individual sewerage

system, other than an individual mechanical plant,

for his own private, personal use. Individual

mechanical plants shall be installed and

maintenance provided by licensed individual

sewerage system installers and/or maintenance

providers only.

B. [Formerly paragraph 13:014-2] A person

installing or providing maintenance of an individual

sewerage system and the person who is the owner

of the premises shall be responsible for compliance

with §§701 and 703.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1347 (June 2002).

§707. Maintenance and Operation

[formerly paragraph 13:015]

A. Individual sewerage systems shall be kept in

service and in a serviceable condition sufficient to insure

compliance with this code and in order to avoid creating

or contributing to a nuisance or a public health hazard.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1347 (June 2002).

§709. Septic Tank Systems

[formerly paragraph 13:016]

A. Where a community-type sewerage system is not

available, a septic tank system may be used provided

that the requirements of §§511.B, 701, 703.A, and 705

are complied with.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1347 (June 2002).

§711. Individual Mechanical Plants

[formerly 13:017-1]

A. An individual mechanical plant may be used where

a community-type system is not available, and where the

state health officer determines that a conventional septic

tank system (septic tank-absorption field) would not be

expected to function properly, and where the

requirements of §§511.B, 701, 703.B, and 705 are

complied with.

B. [Formerly paragraph 13:017-2] Permits, per the

requirements of §701, for the installation of individual

mechanical plants, shall not be issued except and unless

the manufacturer of the mechanical plant has received a

manufacturers license in accordance with the

requirements of §735.A, and has received appropriate

certification from DHH/OPH.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1347 (June 2002).

§713. Other Individual Sewerage Systems

[formerly paragraph 13:018-1]

A. Where a person proposes innovative processes or

design features other than those described in Chapter 7

Subchapter B of this Part, a limited number of

experimental or developmental installations may be

approved where: either failure of the installation or

insignificant benefits to performance and cost is not

expected, based on current engineering data and

literature. The total number of such installations

shall not exceed three throughout the state and

shall be approved under the following conditions.

B. [Formerly paragraph 13:018-2] Each

installation shall be installed only in accordance

with plans and specifications and testing procedures

which have been specifically approved for each

installation as a part of a permit issued by the state

health officer prior to the installation.

C. [Formerly paragraph 13:018-3] The permit for

each installation shall be for a period of one year

and may be renewed under the provisions of §713.

D. [Formerly paragraph 13:018-4] Should an

innovative process fail, the owner of the premises

and the person proposing the innovative process

shall upgrade or replace the installation to bring it

into compliance with the applicable provisions of

this Part.

E. [Formerly paragraph 13:018-5] After the

experimental or developmental use of an

installation is completed, the permit issued under

this Section may be revised to remove the

restrictions cited in Subsections 713.B and C if the

state health officer determines that the available

data show that continued use of the installation will

not result in non-compliance with applicable

provisions of this Chapter. Such a revision of a

permit issued under §713 shall apply only to the

individual installation approved under that permit,

and should not be construed as being an approval of

the system design for other existing or future

installations.

F. [Formerly paragraph 13:018-6] Proprietary

Devices. Proprietary devices are all devices designed

to reduce, process, and treat all or a select portion

of wastewater generated within the individual

home. This includes water recycle and reuse

devices, water conservation devices, composting

units, and other devices intended to reduce the

volume of waste generated or water consumed. The

approval of a proposal to utilize a proprietary device

may only be granted by the state health officer.

AUTHORITY NOTE: Promulgated in accordance with R.S.

40:4(A)(6) and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of

Health and Hospitals, Office of Public Health, LR 28:1347 (June

2002).

Subchapter B. Design and Construction

Regulations

[formerly Chapter 13 Appendix A]

§715. Septic Tanks

[formerly Section I of Appendix A]

A. [Formerly paragraph A:1.1 of Appendix A] A septic

tank is a watertight tank made of steel, concrete or other

approved materials in which the settleable solids of

sewage settle out and are largely changed into liquids or

gases by bacterial decomposition. The remaining residue

in the tank is a heavy, black semi-liquid sludge which

must be removed from the tank periodically. Although

the completely digested sludge contains relatively few

disease germs, in cleaning the tank it is impossible to

remove the digested sludge without removing some

undigested material. Therefore, it is particularly

important that the removed sludge be disposed of in a

safe manner. There are commercial service companies

that will contract for septic tank cleaning and sludge

disposal. Such commercial services are controlled by a

permit system in accordance with §901 of this Part.

B. [Formerly paragraph A:1.2 of Appendix A] Multiple

compartment septic tanks or single chamber septic tanks

in series provide more effective treatment than single

chamber tanks of the same total capacity; therefore, the

use of multiple compartment tanks or single tanks in

series is encouraged. However, single chamber septic

tanks are acceptable.

C. [Formerly paragraph A:1.3 of Appendix A] The

velocity of flow through the tanks must be such that

maximum solids and scum retention is achieved. Vertical

cylindrical tanks must have horizontal (inlet-to-outlet)

separation of at least 24 inches.

1. Tees or baffles must be used at the inlet. The

outlet must be designed so as to preclude floating solids

from escaping from the tank. The inlet tee or baffle

diverts the incoming sewage toward the bottom of the

tank without disturbing the scum which forms on the

surface of the liquid, and the outlet prevents the surface

scum from flowing out of the tank.

D. [Formerly paragraph A:1.4 of Appendix A] The

minimum total septic tank liquid capacity required is 2

1/2 times the estimated average daily design flow.

Sewage loading criteria for determining the average daily

design flow and organic loading are contained in Chapter

15 of this Part. One-bedroom residences may, however,

utilize a 500 gallon tank.

NOTE: The minimum allowable total septic tank volume

for all applications is 500 gallons.

E. [Formerly paragraph A:1.5 of Appendix A] The

distance between the inlet and outlet openings in

the tank wall, measured horizontally, shall be not

less than 24 inches. The distance between the inlet

and outlet shall exceed the width of rectangular and

oval-shaped tanks.

F. [Formerly paragraph A:1.6 of Appendix A] The

tank shall operate with a liquid depth between a

minimum of

30 inches and a maximum of 72 inches measured

vertically from the invert of the outlet (overflow

level) to the bottom of the tank. Recent septic tank

studies have indicated the shallower tank to be

more efficient and is therefore preferred.

G. [Formerly paragraph A:1.7 of Appendix A] For

tanks having straight vertical sides, the dimension

between the top of the tank and the liquid level

shall not be less than 15 percent of the liquid depth.

In horizontal cylindrical tanks, the volume of the air

space above the liquid shall not be less than 15

percent of the liquid capacity. In the latter case, this

condition is met if the liquid depth (distance from

outlet invert to bottom of tank) is at least 79

percent of the diameter of the tank.

H. [Formerly paragraph A:1.8 of Appendix A] A

single tank may be divided into two or more

compartments by means of internal partitions. Each

compartment shall conform to the dimensions

limitations for complete tanks and shall have a

liquid capacity of at least 250 gallons. The total

liquid capacity shall conform to the requirements

for single chamber tanks. No tanks shall have more

than three compartments.

I. [Formerly paragraph A:1.9 of Appendix A] The

tank shall be constructed of materials which are

corrosion resistant and provide a watertight

permanent structure. The cover of the tank shall be

designed for a dead load of not less than

150 pounds per square foot. Concrete covers must

be reinforced with steel and must be not less than

4 inches thick. Metal septic tanks shall comply with

the requirements of §715.O. Tanks of other

materials such as fiberglass will be reviewed for

acceptance on an individual basis. They will be

required to comply generally with the basic

applicable standards for metal septic tanks.

J. [Formerly paragraph A:1.10 of Appendix A] Access

to the septic tank for cleaning and inspection shall be

provided by a removable cover or manhole. Both inlet

and outlet devices as well as each compartment in

multiple compartment tanks must be accessible.

Manholes, when used shall be at least 20 inches square

or 24 inches in diameter and provided with covers which

can be sealed watertight. Septic tanks with removable

covers must be provided with an 8-inch inspection hole

over the inlet and the outlet.

K. [Formerly paragraph A:1.11 of Appendix A] Either

tees or baffles shall be provided at the inlet of the tank

and shall extend upward at least 6 inches above the

liquid level of the tank. The inlet tee or baffle shall

extend downward to at least 6 inches below the liquid

level, but it shall not extend below the level of the lower

end of the outlet tee or baffle. At least 2 inches of open

space shall be provided above the baffle or tee to

provide ventilation to the tank through the building

plumbing system.

L. [Formerly paragraph A:1.12 of Appendix A] On the

outlet side the tee or baffle shall extend downward to a

distance below the water surface equal to 40 percent of

the liquid depth of tanks with vertical sides and 35

percent of liquid depth of tanks of other shapes as

measured to the nearest inch. If a tee or baffle is used in

the outlet the upper end shall extend 6 inches above the

liquid level.

M. [Formerly paragraph A:1.13 of Appendix A] Inlet

and outlet fittings (tees or ells) must be of cast iron,

schedule 40 PVC or ABS plastic or other approved

material.

N. [Formerly paragraph A:1.14 of Appendix A] The

invert of the inlet shall be located at least 2 inches above

the invert of the outlet.

O. [Formerly paragraph A:1.15 of Appendix A] Metal

septic tanks shall be prefabricated of a minimum of 14

gauge commercial grade steel. Corrosion protection

shall, at a minimum, consist of a hot-dipped asphalt

coating of at least 0.025-inch thickness properly applied

to all surfaces of the new, clean, bare metal.

P. [Formerly paragraph A:1.16 of Appendix A] The

location of a septic tank shall comply with minimum

distance requirements from water wells, water lines, etc.

as contained in Part XII, of this Code.

Q. [Formerly paragraph A:1.17 of Appendix A] The use

of septic tanks in series is encouraged. The first tank shall

have at least a 500-gallon liquid capacity and all

subsequent tanks shall have at least 300-gallon

liquid capacities. The total capacity of all tanks in

series must comply with the capacities for septic

tanks as prescribed in §715.D.

R. [Formerly paragraph A:1.18 of Appendix A]

Piping from the house to the septic tank must be

such that the waste flow does not disturb the

retention of scum and sludge in the tank. To attain

this, the inlet piping from the house must have a

minimum diameter of four inches and be laid on a

slope of at least 1/8 inch per foot. The slope for the

last 10 feet of line preceding the septic tank must

not exceed 1/4 inch per foot. All plastic piping,

excluding perforated pipe, must be a minimum of

SDR 35 sewer and drainage pipe or equivalent.

S. [Formerly paragraph A:1.19 of Appendix A]

Backfill around septic tanks must be made in thin

layers thoroughly tamped in a manner that will not

produce undue strain on the tank. Sufficient soil

cover can be provided over the top of the septic

tank to permit grass growth. However, no other

obstruction to access (i.e., concrete slabs, buildings,

etc.) shall be allowed.

T. [Formerly paragraph A:1.20 of Appendix A]

Septic tanks should be inspected every six years and

pumped at least every eight years by a licensed

sewage hauler.

U. [Formerly paragraph A:1.21 of Appendix A]

Untreated or uncoated metal septic tanks shall not

be used.

V. [Formerly paragraph A:1.22 of Appendix A]

Abandoned septic tanks (tanks no longer in active

use) shall be pumped out by a licensed sewage

hauler, then removed or the cover discarded and

the tank filled with soil to natural grade. The

contents of the abandoned tank shall not be placed

into a newly installed individual sewerage system.

AUTHORITY NOTE: Promulgated in accordance with R.S.

40:4(A)(6) and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of

Health and Hospitals, Office of Public Health, LR 28:1348 (June

2002).

§717. Septic Tank Effluent

[formerly Section II of Appendix A]

A. [Formerly paragraph A:2.1 of Appendix A]

There is a common belief that sewage after

treatment in a septic tank is pure water, or very

nearly so. This is false. The effluent or liquid flowing

from the tank is still foul and dangerous. The septic

tank cannot be depended upon to remove disease

germs. The discharge of the effluent from septic tanks

into street gutters, surface ditches, or streams is

prohibited.

B. [Formerly paragraph A:2.2 of Appendix A] The

treatment level of a septic tank is referred to as primary

treatment.

C. [Formerly paragraph A:2.3 of Appendix A] The

preferred method of treatment for septic tank effluents

is accomplished through the use of soil absorption

trenches. Small oxidation ponds or sand filter beds may

be used in lieu of absorption trenches only where soil

and drainage conditions or available space prevent the

use of absorption trenches. The level of treatment of

these units is referred to as secondary treatment.

D. [Formerly paragraph A:2.4 of Appendix A] The use

of absorption trenches, oxidation ponds and filter beds

for the treatment of septic tank effluents is discussed in

detail in the following Paragraphs of these standards.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1349 (June 2002).

§719. Absorption Trenches

[formerly Section III of Appendix A]

A. [Formerly paragraph A:3.1 of Appendix A] Where

soil conditions are satisfactory and sufficient land is

available, septic tank effluent shall be disposed of in

absorption trenches. This consists of a system of covered

gravel (or other approved aggregate) filled trenches into

which the septic tank effluent is applied so as to permit

the liquid to seep into the soil. By action of

microorganisms in the soil, the organic matter is

converted into mineral compounds.

B. [Formerly paragraph A.3.2 of Appendix A] A

number of variables determine whether an absorption

trench is feasible, including: soil porosity (permeability),

ground water table, available space, and the rate at

which septic tank effluent enters the soil (percolation

rate). In general three conditions should be met.

1. The soil percolation rate must be within the

acceptable range.

2. The maximum elevation of the ground water

table should be at least 2 feet below the bottom of the

proposed trench system.

3. Clay formations or other impervious strata

should be at a depth greater than 4 feet below the

bottom of the trenches.

C. [Formerly paragraph A.3.3 of Appendix A]

Unless these conditions are satisfied, the site is

unsuitable for a subsurface sewage disposal system,

and an alternative method must be utilized.

D. [Formerly paragraph A.3.4 of Appendix A] The

acceptability of soil for an absorption trench system

and the required size of such a system is currently

based upon the "Percolation Test" described below.

1. Three or more tests must be made in

separate test holes spaced uniformly over the

proposed absorption field site.

2. Dig or bore a hole, with horizontal

dimensions of from 4 to 12 inches and vertical sides

to the depth of the proposed absorption trench. In

order to save time, labor, and volume of water

required per test, the holes may be bored with a 4-

inch auger.

3. Carefully scratch the bottom and sides of

the hole with a knife blade or sharp-pointed

instrument in order to remove any smeared soil

surfaces and to provide a natural soil interface into

which water may percolate. Remove all loose

material from the hole.

4. To conduct the test, fill the hole with clear

water. This pre-wetting procedure should normally

be accomplished on the day prior to the percolation

rate measurement. This procedure is to insure that

the soil is given ample opportunity to swell and to

approach the operating condition of the wet season

of the year. Thus, the test should give comparable

results in the same soil whether made in a dry or in

a wet season.

5. With the exception of sandy soils,

percolation rate measurements shall be made on

the day following the procedure described under

§719.D.4 above. Add water until the liquid depth is

at least 6 inches, but not more than 12 inches from

a fixed reference point. Measure the drop in water

level over a 60-minute period. This drop is used to

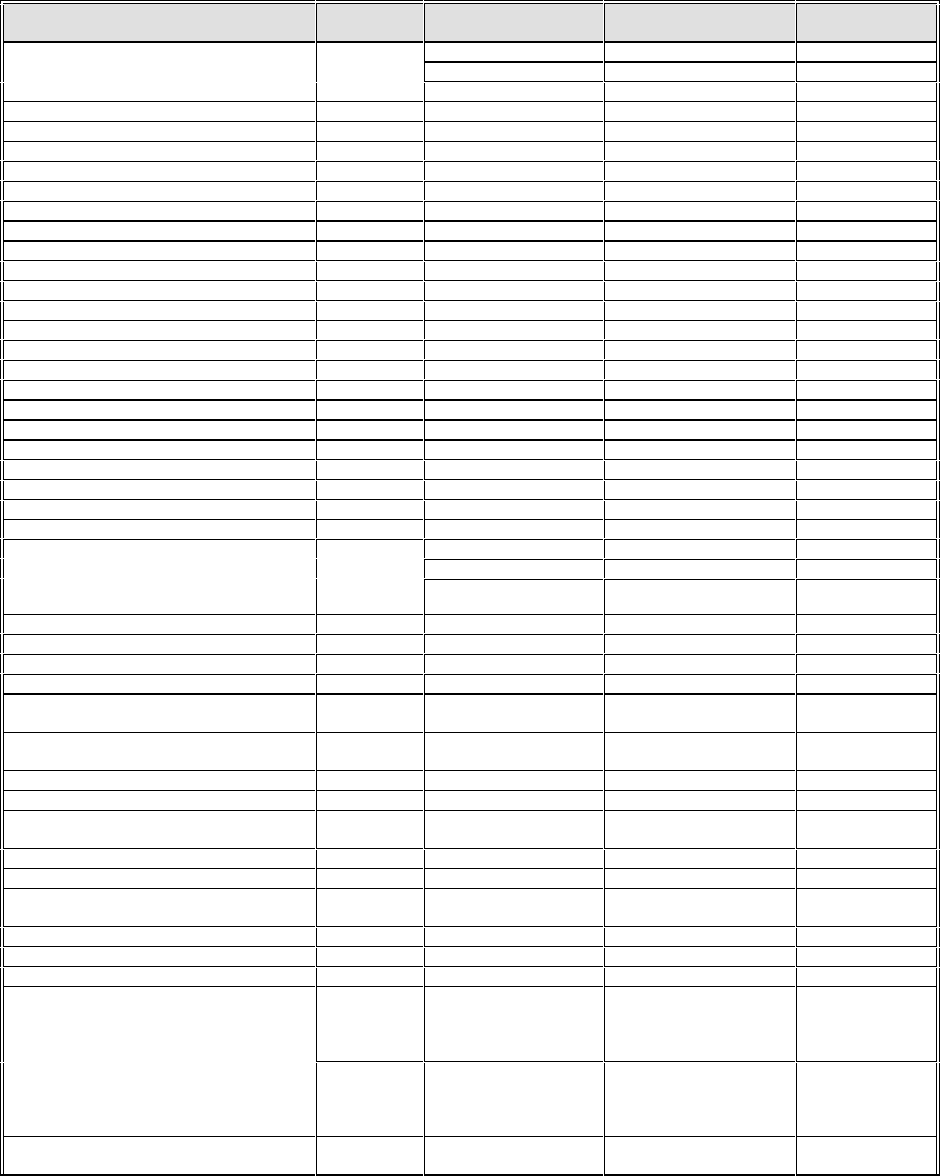

calculate the percolation rate. Section 1501.B.1

(Figure 1) shows methods of percolation rate

measurement. If the drop in liquid depth in the first

30 minutes is less than one inch, it is unnecessary to

continue the test for the full 60-minute period.

6. The distance the water falls in 60 minutes in

each of the three test holes is recorded. The average

drop for the three holes is used to determine the

total length of absorption trench from Table 1 below.

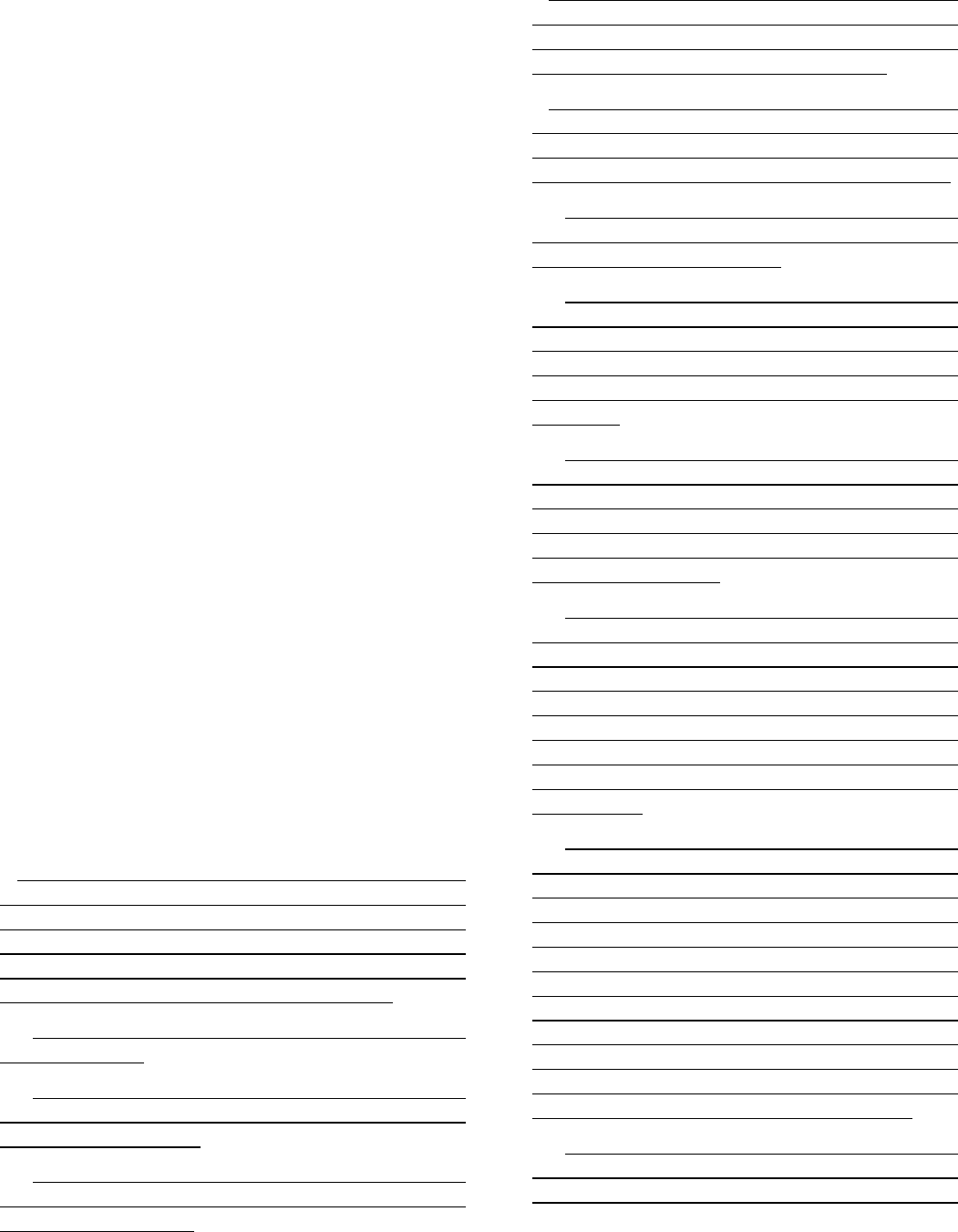

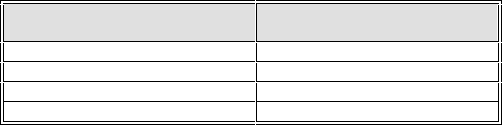

Table 1

Absorption Trench Length

Requirements for Individual Residences

Average Water Level Drop in

60 minutes

(in inches)

Length (in Feet) of Absorption

Trenches Required per

Bedroom*

More than 12

72

12

83

11

87

10

91

9

96

8

100

7

104

6

110

5

117

4

127

3

142

Less than 3

Not acceptable for absorption

field

NOTE: A minimum of 160 linear feet of field line shall be

provided.

*-or per 150 gpd of design flow for non-residential applications.

E. [Formerly paragraph A:3.5 of Appendix A] Many

different designs may be used in laying out an absorption

trench system. The choice will depend on the size and

shape of the available disposal area, the capacity

required and the topography of the area.

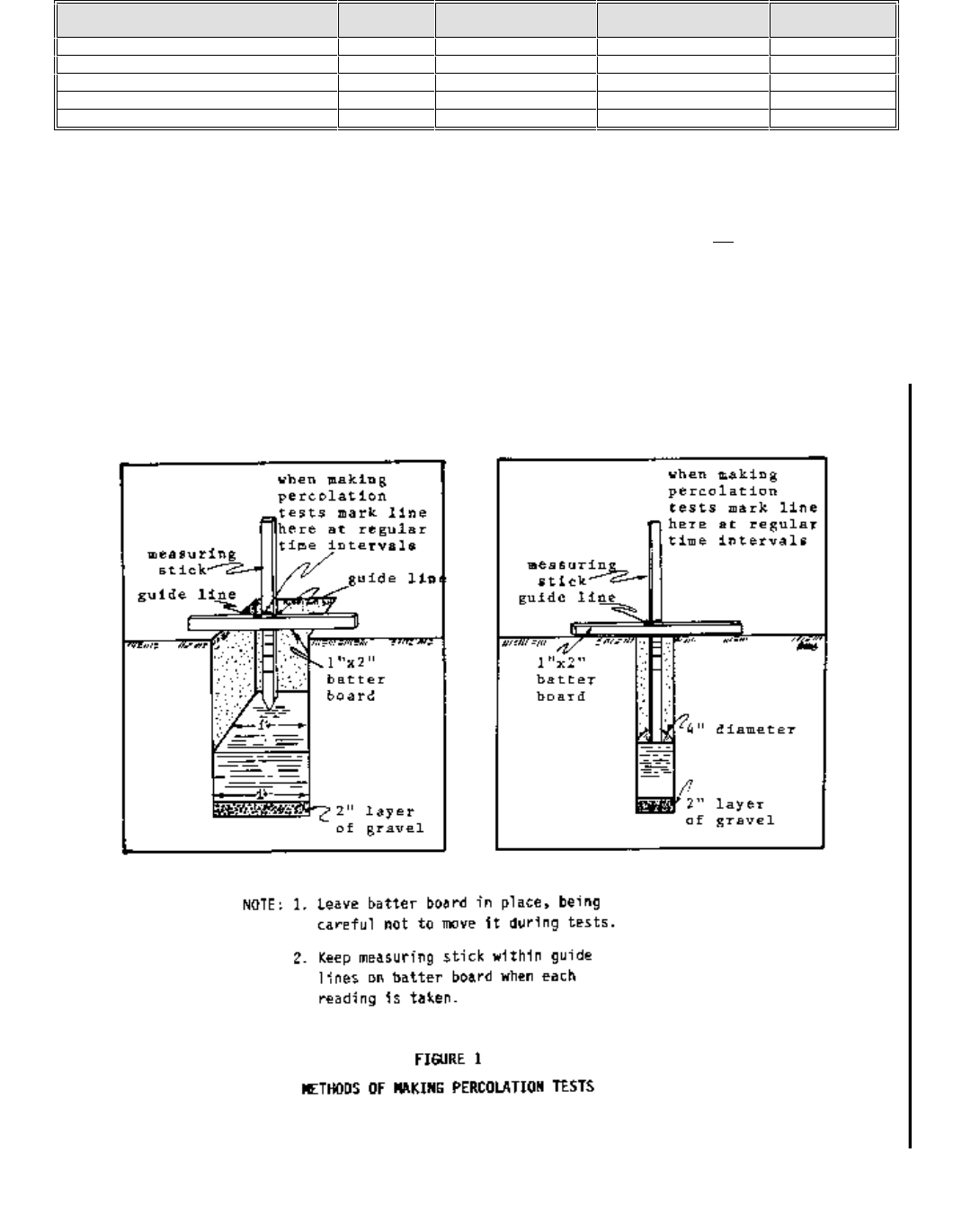

F. [Formerly paragraph A:3.6 of Appendix A] The

septic tank effluent is applied to the absorption field

through a system of level bottomed trenches.

Conventional field lines are laid on a slope of 2 to 3

inches per 100 feet. Gravelless pipe and other

distribution chambers must be laid as close as possible to

a slope of 1 inch per 100 feet. A distribution box may be

required for equal distribution of the effluent. Section

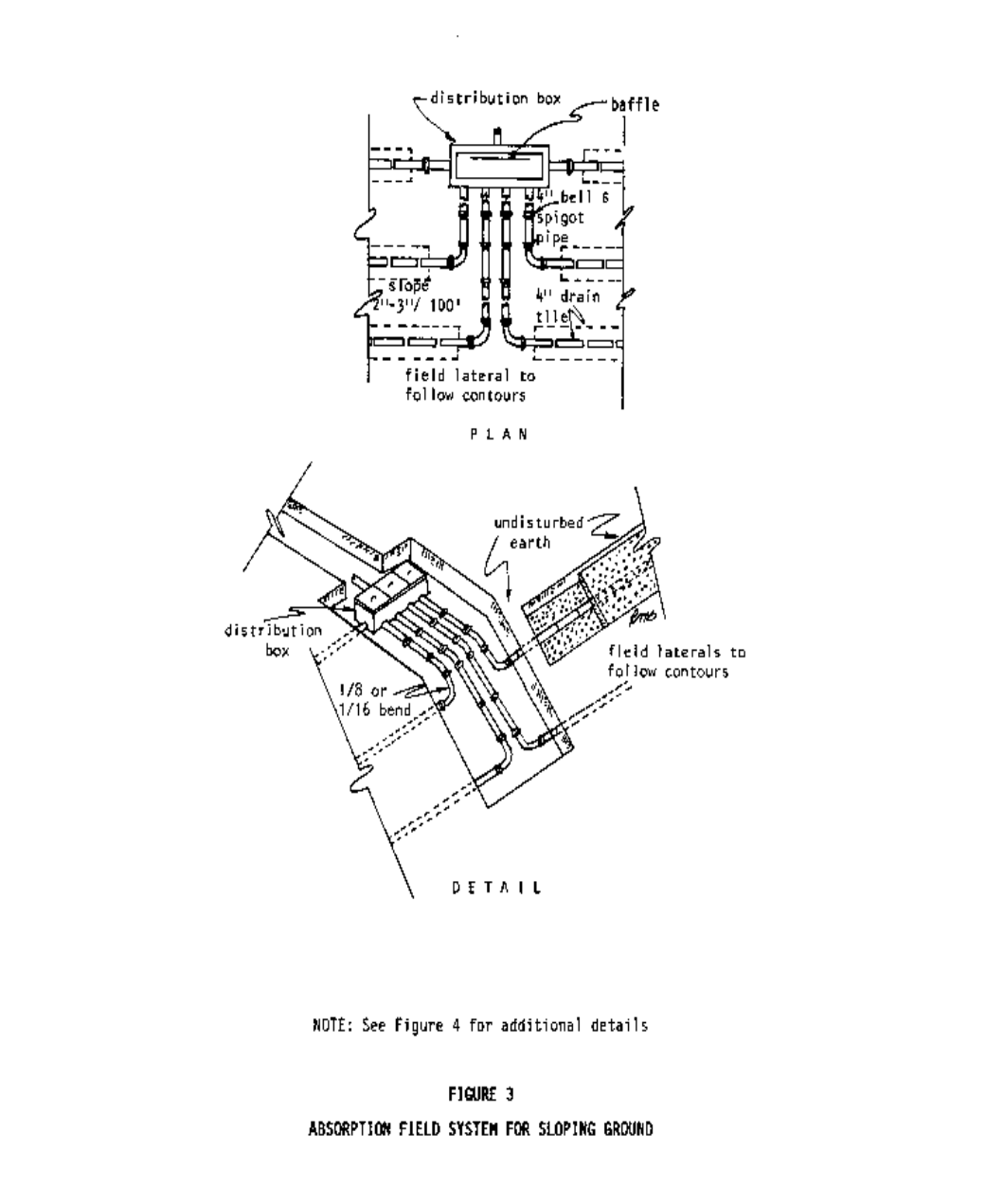

1501.B.2 and 3 (Figure 2 and 3) show a typical layout of a

conventional absorption trench system for flat and

sloping areas.

G. [Formerly paragraph A:3.7 of Appendix A] To

provide the minimum required backfill depth and earth

cover, the depth of the absorption trenches must be a

minimum of 18 inches. Additional depth may be needed

for contour adjustment for extra backfill under the

distribution line or for other design purposes. However,

the total depth must not exceed 24 inches.

H. [Formerly paragraph A:3.8 of Appendix A] Careful

construction is important in obtaining a satisfactory soil

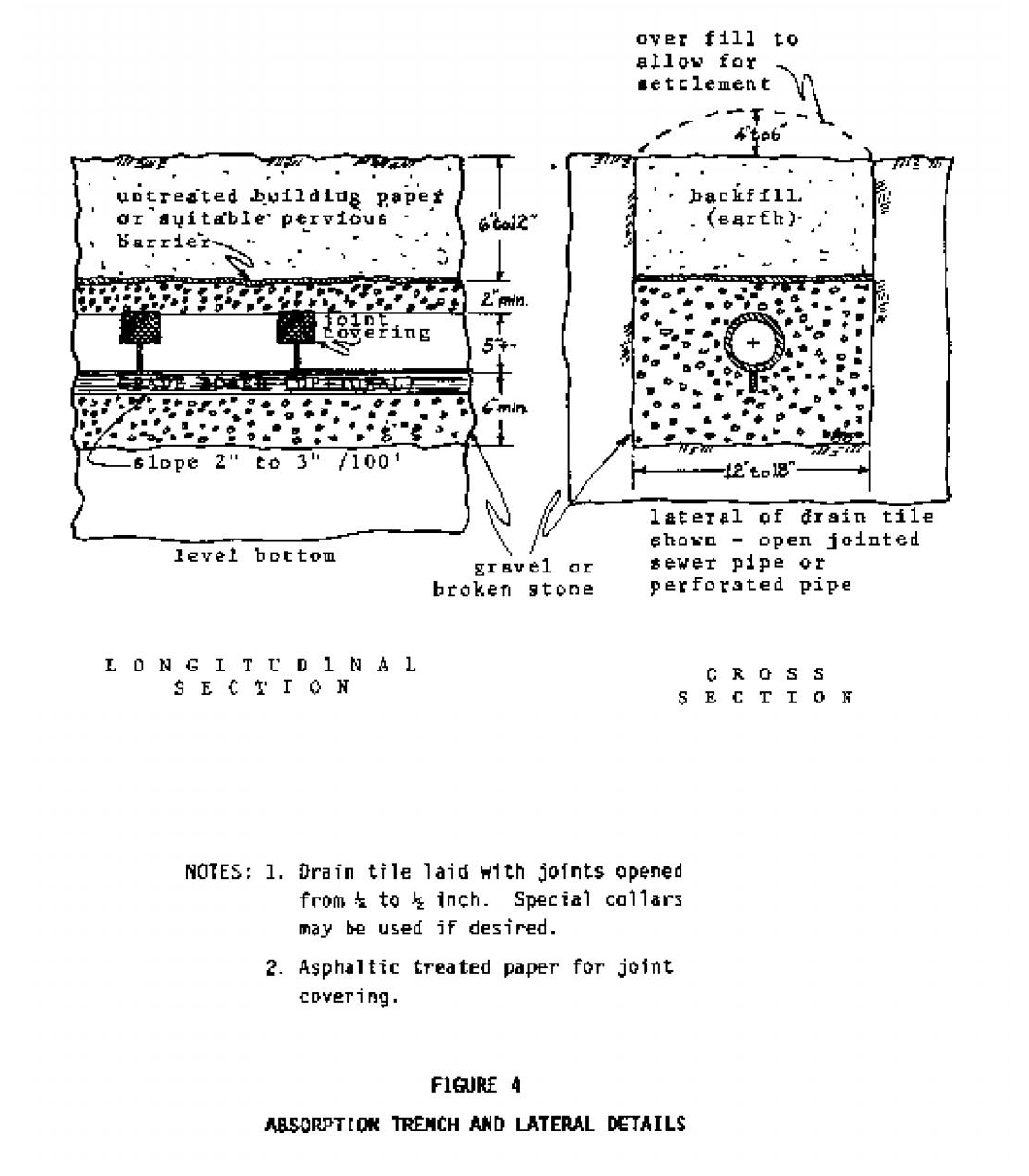

absorption system. Section 1501.B.4 (Figure 4) shows

details for absorption trench construction.

I. [Formerly paragraph A:3.9 of Appendix A]

Individual trenches shall not be greater than 100 feet in

length and not less than 18 inches in width. The center

line distance between individual trenches shall be at

least 6 feet. In addition, the absorption trenches

shall be located at least 10 feet from any dwelling or

property line.

J. [Formerly paragraph A:3.10 of Appendix A]

The location of the absorption trenches shall

comply with minimum distance requirements from

water wells, water lines, etc., as contained in Part XII

of this Code.

K. [Formerly paragraph A:3.11 of Appendix A] In

every case, at least two trenches shall be used.

L. [Formerly paragraph A:3.12 of Appendix A]

Trench bottoms must be level to promote even

distribution, thereby minimizing premature failure

of a portion of the trench. During excavation,

attention must be given to the protection of the

soil. Care must be taken to prevent sealing of the

surface on the bottom and sides of the trench.

Trenches should not be excavated when the soil is

wet enough to smear or compact easily. All smeared

or compacted surfaces must be raked to a depth of

1 inch and loose material removed before the

backfill is placed in the trench.

M. [Formerly paragraph A:3.13 of Appendix A]

Conventional field lines shall consist of perforated

non-metallic pipe meeting one of the following

standards.

PVC sewer pipe and fittings (Thin wall), ASTM D2729-93

Smooth wall polyethylene (PE) pipe, ASTM F810-93, for use in

waste disposal absorption fields;

SRP pipe and fittings, ASTM D2852-93.

1. In every case, the minimum acceptable

diameter is

4 inches. Although the trench bottom is level,

conventional field pipes must be laid on a slope of

between 2 to 3 inches per 100 feet to provide even

distribution of the liquid throughout the trench.

N. [Formerly paragraph A:3.14 of Appendix A]

Where conventional field pipe is used, it must be

surrounded by clean graded gravel or rock, broken,

hard-burned clay brick or similar material. The bed

material may range in size from

1/2 inch to 2.5 inches. The gravel must extend from

at least

2 inches above the top of the pipe to at least 6

inches below the bottom of the pipe. The top of the

stone should be covered with either untreated

building paper, or similar pervious material to

prevent the gravel from becoming clogged by the earth

backfill [see §1501.B.4 (Figure 4)].

O. [Formerly paragraph A:3.15 of Appendix A] Where

gravelless pipe or distribution chambers are used, the fill

must be porous soil or sand which allows the passage of

water in

all directions with a 6-inch layer below the pipe and filled

4 to 6 inches above grade and spread 3 to 4 feet on

either side of the trench. Only gravelless pipe or other

distribution chambers specifically approved for use in

Louisiana by the state health officer may be used. The

total length of gravelless distribution products required is

the same as for conventional absorption trenches.

P. [Formerly paragraph A:3.16 of Appendix A] For an

absorption trench to work properly, it must have access

to air, generally through the soil interstices of the

backfill. Therefore, the absorption trench should be

backfilled with 4 to 12 inches of pervious soil, hand-

tamped and then overfilled with about

4 to 6 inches of earth. Care should be taken to avoid

compacting of the backfill.

Q. [Formerly paragraph A:3.17 of Appendix A] All of

the above listed requirements, with the exception of the

protection of water supplies, are aimed at preventing

absorption trench clogging and premature failure. In

addition, the septic tank should be inspected every six

years after installation and pumped, as necessary, to

prevent solid overflow to the soil absorption system and

subsequent clogging and failure.

R. [Formerly paragraph A:3.18 of Appendix A]

Absorption trenches shall not be located:

1. beneath driveways, parking or other paved

areas;

2. in areas that may be subjected to passage or

parking of heavy equipment or vehicles, or storage of

materials;

3. beneath buildings or other structures.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1349 (June 2002).

§721. Oxidation Ponds

[formerly Section IV of Appendix A]

A. [Formerly paragraph A:4.1 of Appendix A] An

oxidation pond is a shallow pond designed specifically to

treat sewage by natural purification processes under the

influence of air and sunlight. The stabilization process

consists largely of the interactions of bacteria and algae.

Bacteria digest and oxidize the constituents of

sewage and render it harmless and odor free. Algae

utilize carbon dioxide and other substances

resulting from bacterial action and through

photosynthesis produce the oxygen needed to

sustain the bacteria in the treatment process.

During the detention period, the objectionable

characteristics of the sewage largely disappear.

B. [Formerly paragraph A:4.2 of Appendix A] The

minimum surface area of an oxidation pond must be

no less than 400 square feet with a 4 to 5 foot

average liquid depth and vertical side walls. This

minimum size pond is adequate for design flows of

up to 400 gallons/day (gpd). For design flows in

excess of 400 gpd, the pond area must be increased

to provide sufficient volume (at the 4 foot depth) to

hold 30 days worth of flow (a 30-day retention

period). For wastes with high BOD loadings, special

consideration for increasing pond size must be

given.

C. [Formerly paragraph A:4.3 of Appendix A]

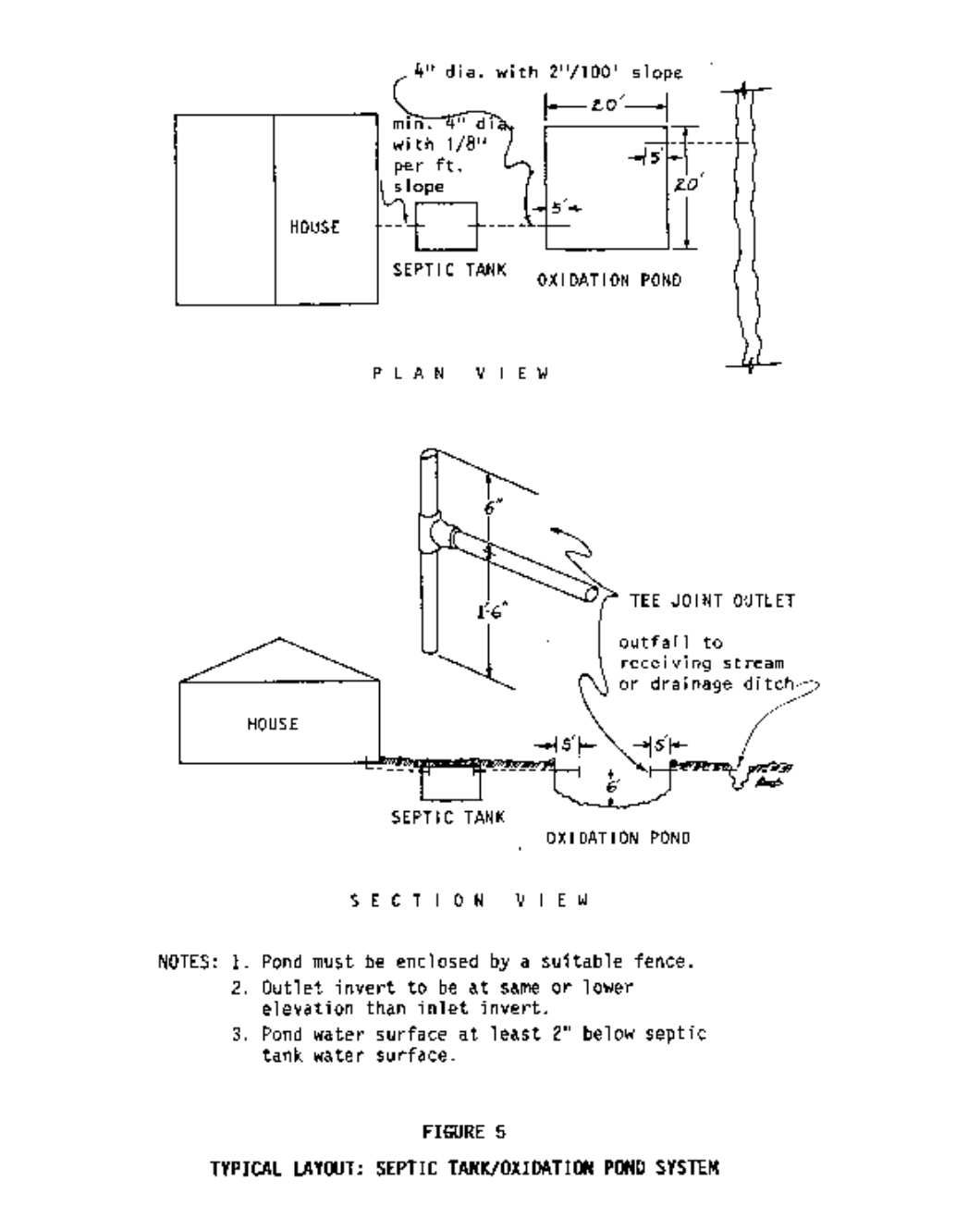

Section 1501.B.5 (Figure 5) shows a typical layout

for a septic tank-oxidation pond system. The actual

layout of any pond system will be governed to a

great extent by the topography of the particular

location. However, an oxidation pond must be

located so as to comply with the minimum distance

requirements from water wells, lines, etc., as

contained in Part XII of this Code. It is also desirable

for aesthetic reasons to locate it as far as possible,

but at least 50 feet from any dwelling and no less

than 20 feet from the property line to water's edge

at normal operating line.

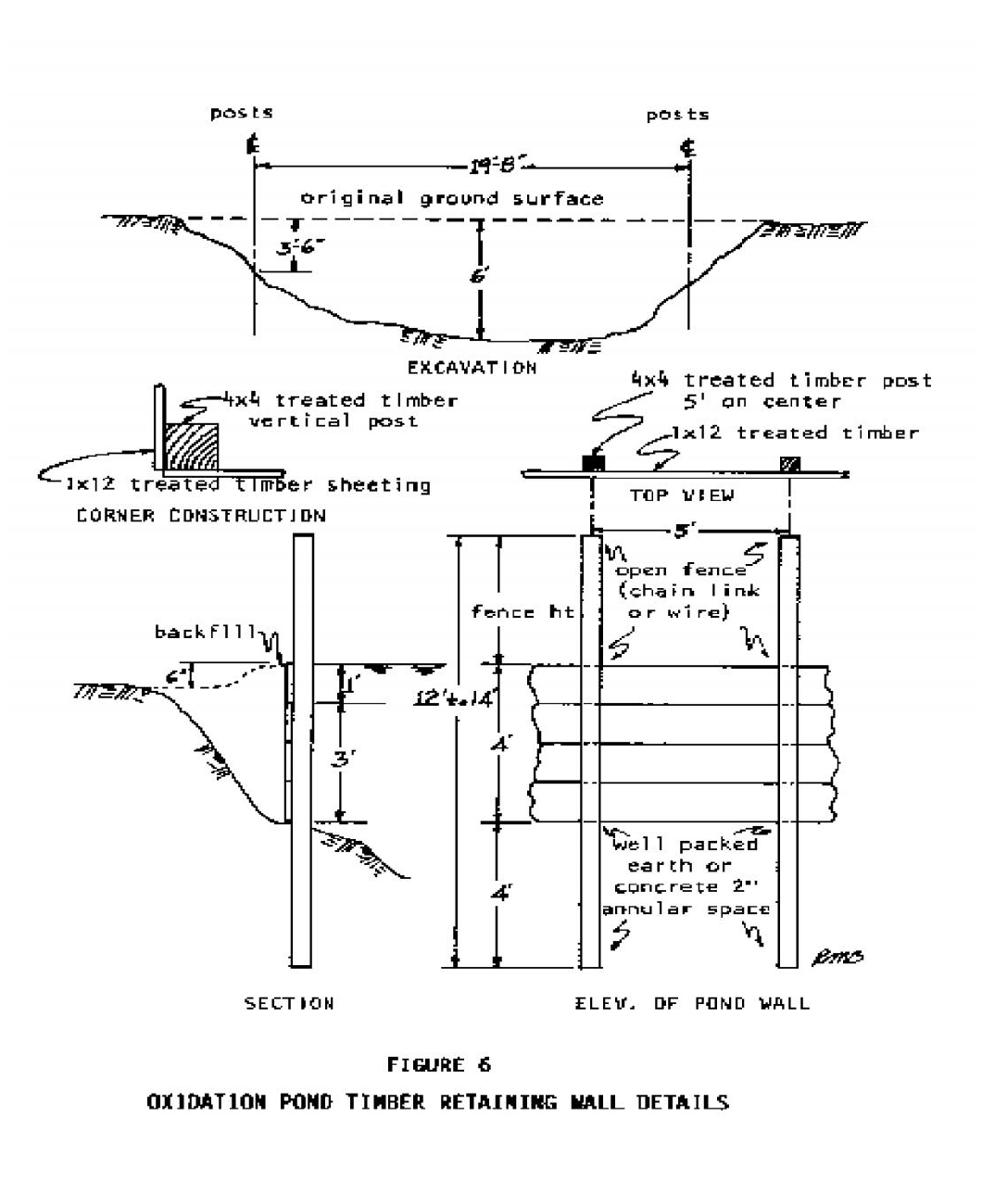

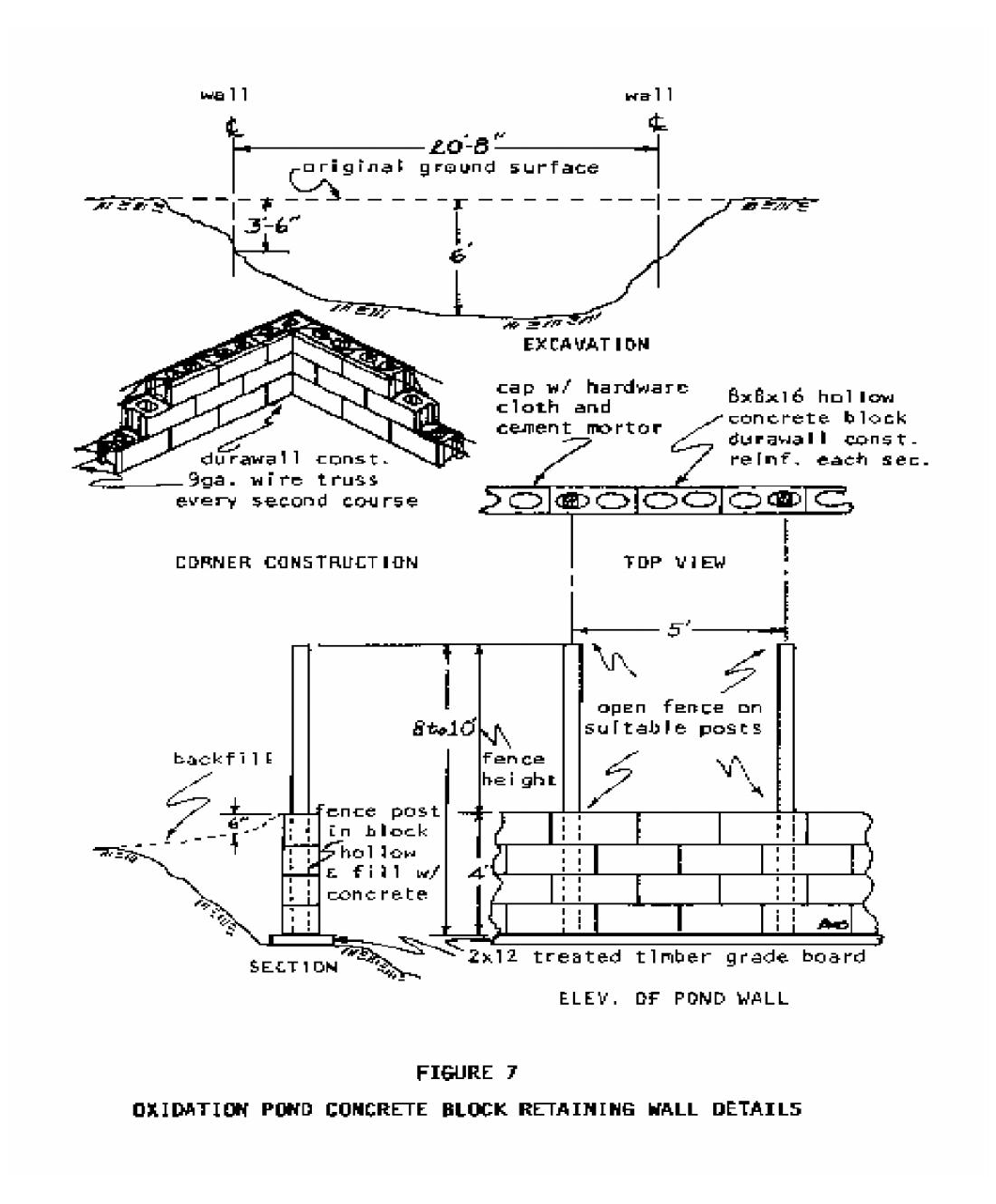

D. [Formerly paragraph A:4.4 of Appendix A] As

mentioned, the use of the minimum surface area of

400 square feet requires that an oxidation pond be

furnished with vertical side walls so that an

adequate volume for treatment is provided. Section

1501.B.6 (Figure 6) shows a type of construction

utilizing treated timber which under normal soil

conditions is acceptable for the vertical side walls of

a 20 foot by 20 foot oxidation pond with a 5 foot

average water depth. Section 1501.B.7 (Figure 7)

shows a similar type of construction utilizing

concrete blocks. Either of these designs requires

very little maintenance.

E. [Formerly paragraph A:4.5 of Appendix A]

Vertical side walls must be of cypress or treated

timbers or concrete blocks and so constructed as to

provide a permanent structure.

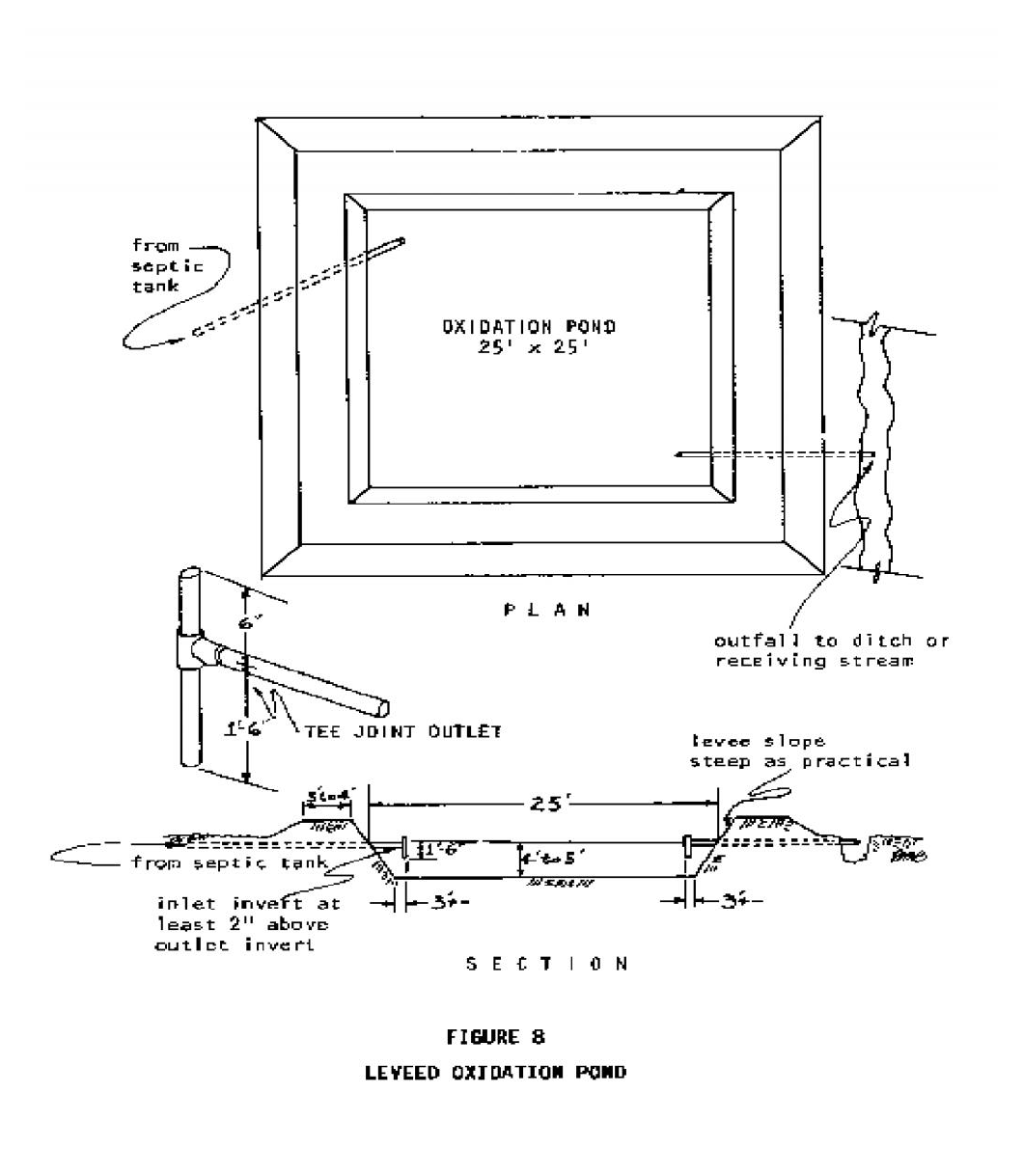

F. [Formerly paragraph A:4.6 of Appendix A]

Although not encouraged, a pond may be constructed

with sloping sides and earthen levees. Such a design is

shown in §1501.B.8 (Figure 8). The design requires a

minimum surface area of 625 square feet with a 5 foot

liquid depth at the center in order to achieve the

required volume. The cost of this design is less than that

of the vertical wall ponds referred to above, but more

space is needed and routine maintenance requirements

such as levee mowing are greater. The slope of the

natural earth side walls must not be shallower than one-

to-one (45-degree angle) [see §1501.B.8 (Figure 8)].

G. [Formerly paragraph A:4.7 of Appendix A] A septic

tank must precede the oxidation pond and must comply

with the septic tank requirements presented in these

regulations.

H. [Formerly paragraph A:4.8 of Appendix A] The pipe

from the septic tank to the pond as well as the outfall

pipe from the pond must be at least 4 inches in diameter

and placed at a minimum slope of 2 inches per 100 feet.

The inlet must extend 4 to 6 feet horizontally into the

pond and be directed downward at least 1 1/2 to 2 feet

below the liquid surface level. The outlet must extend 4

to 6 feet horizontally into the pond and consist of a tee

with the invert set at the operating water level of the

pond. One leg of tee must be open and extend above the

water level, while the down leg is extended 1 1/2 to 2

feet below the water level. The invert of the pond outlet

must be lower than the pond inlet invert [see §1501.B.8

(Figure 8)]. Additionally the invert of the pond inlet must

be at least 2 inches lower than the invert of the septic

tank outlet.

I. [Formerly paragraph A:4.9 of Appendix A] The

pond shall be enclosed by a suitable non-climbable fence

to keep out children, pets and livestock. An open type

fence (woven wire) is preferable because it will not

restrict sunlight and air which are necessary for the

treatment. The fence shall be at least

5 feet in height and be provided with a locked gate.

J. [Formerly paragraph A:4.10 of Appendix A]

Abandoned oxidation ponds (ponds no longer in active

use) shall be dewatered, allowed to dry and then filled

with soil to natural grade.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1351 (June 2002).

§723. Sand Filter

[formerly Section V of Appendix A]

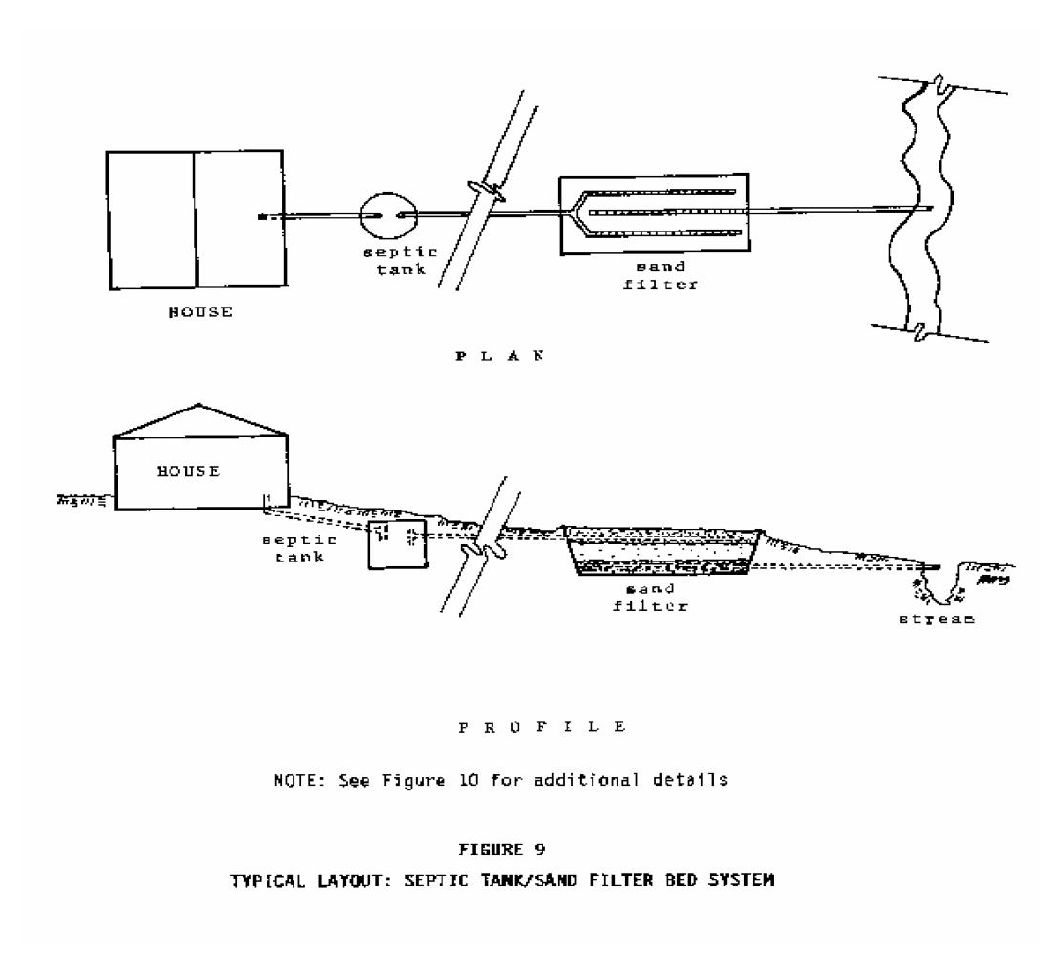

A. [Formerly paragraph A:5.1 of Appendix A]

Another alternative for the secondary treatment of

septic tank effluent is a deep-type sand filter bed.

Treatment in a sand filter bed is accomplished by

the action of microorganisms in a sand bed in which

the suspended solids of the septic tank effluent

have been trapped by filtration. It is important that

the sand bed remain aerobic throughout the

treatment process. This is accomplished by exposing

the sand surface to the air as much as possible on a

continuous basis. Of course, the best way this can

be done is to place no cover whatsoever over the

sand bed. Since this is not aesthetically desirable for

homes, a coarse gravel cover of clean, washed

gravel, not to exceed 6 inches in depth over the bed

is permitted. No other cover is acceptable. A filter

bed system is shown in §1501.B.9 (Figure 9).

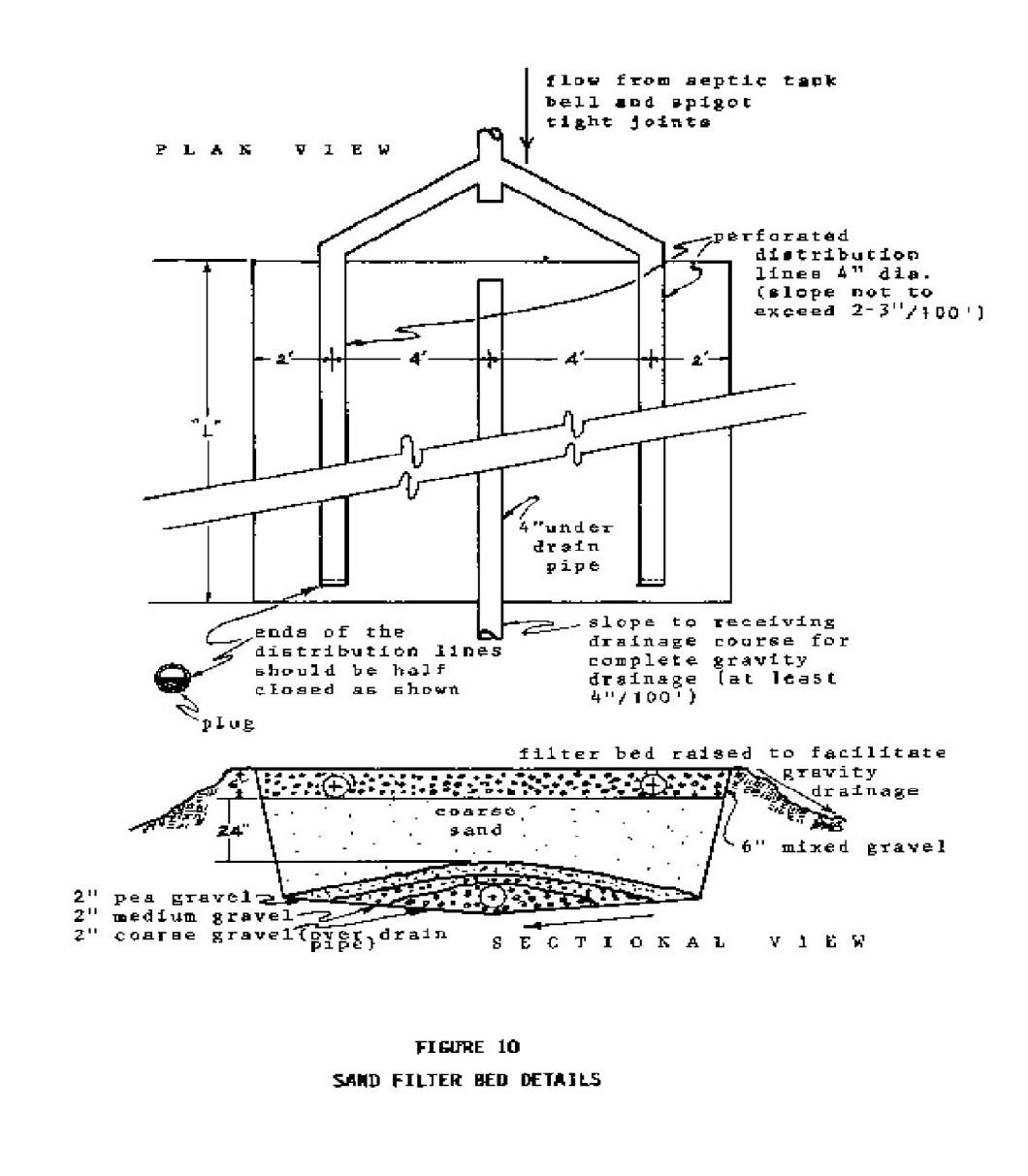

B. [Formerly paragraph A:5.2 of Appendix A] The

sand filter bed is constructed by placing perforated

pipe near the bottom of a rectangular area of the

required size in a layer of gravel covered by a layer

of coarse sand 24 inches deep. On top of this are

placed distribution lines (perforated pipe) likewise

encased in a layer of gravel [see §1501.B.10 (Figure

10)]. The septic tank effluent is distributed speedily

in the gravel cover spreading over the top of the

sand seeping slowly and vertically through the sand

to the bottom layer of gravel to be carried away in

the under drain line.

C. [Formerly paragraph A:5.3 of Appendix A]

Sand filter beds are to be constructed with a

minimum width of 12 feet and a minimum length of

25 feet. This minimum size filter bed is adequately

sized for design flows of up to 400 gpd. For greater

design flows, the required length shall be increased

by eight feet for each additional 150 gpd or portion

thereof.

D. [Formerly paragraph A:5.4 of Appendix A] The

bed must be drained completely. This may require

the bed to be raised above natural ground level.

E. [Formerly paragraph A:5.5 of Appendix A] To

prevent sand infiltration into the underdrain, a layer

of graded gravel must be placed over the

underdrain line and the entire bottom of the filter

bed. All gravel must be clean and washed.

F. [Formerly paragraph A:5.6 of Appendix A] Filter

sand shall conform to the following standard

specifications.

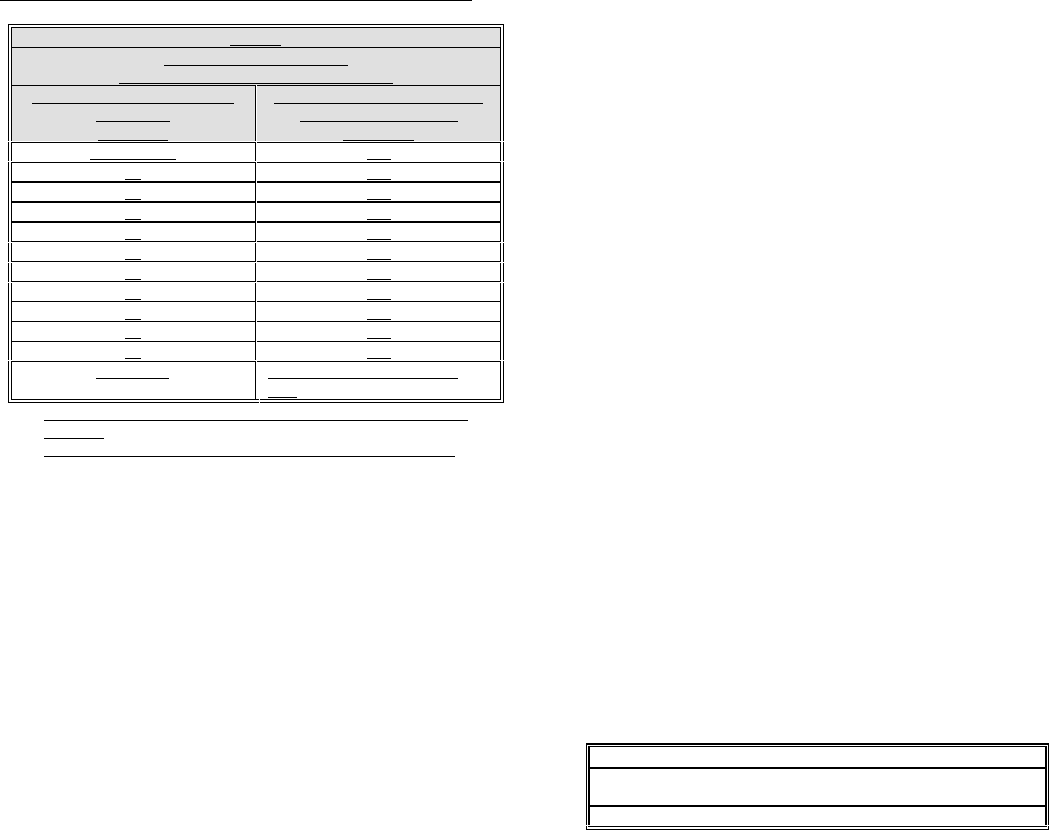

U.S.

Sieve Size

Tyler

Screen Size

% Passing

(By Weight)

Number 4

Number 4

95-100

Number 14

60-80

Number 16

Number 28

5-20

Number 50

Number 48

0-5

Number 100

Number 100

0

G. [Formerly paragraph A:5.7 of Appendix A] At least

two distribution lines must be provided and they must

be sloped 2 inches to 3 inches per 100 feet. The lines

must be 4-inch diameter, 20-inch long farm tile, 2 feet to

3-feet lengths of vitrified clay bell-and-spigot sewer pipe

laid with open joints, or perforated nonmetallic pipe

meeting one of the standards cited in §719.M. The ends

of the distribution lines must be half-closed [see

§1501.B.10 (Figure 10)].

H. [Formerly paragraph A:5.8 of Appendix A]

Underdrain pipe materials are the same as those for the

distribution pipe, however, the slope must be no less

than 4 inches per 100 feet.

I. [Formerly paragraph A:5.9 of Appendix A] The

filter bed must be appropriately protected from surface

runoff water.

J. [Formerly paragraph A:5.10 of Appendix A] The

filter bed must be located no less than 10 feet from the

property line.

K. [Formerly paragraph A:5.11 of Appendix A] The

location of the filter bed shall comply with minimum

distance requirements from water wells, water lines,

etc., as contained in Part XII of this Code.

AUTHORITY NOTE: Promulgated in accordance with R.S. 40:4(A)(6)

and R.S. 40:5(9)(20).

HISTORICAL NOTE: Promulgated by the Department of Health and

Hospitals, Office of Public Health, LR 28:1352 (June 2002).

*Editor's Note: The address cited in §725.G has changed to:

Department of Health and Hospitals

Office of Public Health

Engineering Services Section

P.O. Box 4489

Baton Rouge, LA 70821-4489

§725. Mechanical Waste Water Treatment Plants

[formerly Section VI of Appendix A]

A. [Formerly paragraph A:6.1 of Appendix A]

Mechanical wastewater treatment plants are small

plants capable of providing primary and secondary

treatment of sanitary sewage. All are considered to be

aerobic treatment units.

B. [Formerly paragraph A:6.2 of Appendix A] An

individual mechanical plant will be permitted where

individual sewerage systems would currently be

permitted under prevailing rules as set forth in this

Part of the state sanitary code. Sewage loading

criteria for determining the average daily design

flow and organic loading are contained in Chapter

15 of this Part.

C. [Formerly paragraph A:6.3 of Appendix A] An

individual mechanical plant will be permitted in lieu

of a conventional septic tank system (septic

tank/absorption field) only in accordance with the

provisions of §511.B of this Code, and where a

conventional septic tank system could not be

permitted.

D. [Formerly paragraph A:6.4 of Appendix A]

Permitted individual mechanical plants shall strictly

comply with National Sanitation Foundation

International Standard, NSF 40-1996 for Residential

Wastewater Treatment Systems (Class I Systems) as

revised May 1996 and published by NSF

International, P.O. Box 130140, Ann Arbor, Michigan

48113-0140 USA, and as has been approved by the

American National Standards Institute, 11 West

42nd Street, New York, New York 10036 as standard

ANSI/NSF 40-1996, revised May 28, 1996.

E. [Formerly paragraph A:6.5 of Appendix A] All

individual mechanical plants currently approved for

installation in Louisiana as of the effective date of

these regulations shall not be required to meet the

requirements of §725.D until March 1, 2001. Until

March 1, 2001, plants shall continue to comply with

the standards under which they were approved.

Effective March 1, 2001, all plants shall comply with

the standard as stated in §725.D.

F. [Formerly paragraph A:6.6 of Appendix A] In

addition to evidence of strict compliance with NSF

International Standard NSF 40-1996 (Class I

Systems), and ANSI/NSF 40-1996 (Class I Systems),

as are specified in §725.D of this Code, the following

Department of Health and Hospitals/Office of Public

Health (DHH/OPH) requirements shall also apply.

1. Testing/Evaluation (General)

a. All certifications of individual mechanical

plants shall be conducted by an American National

Standards Institute (ANSI) accredited certification

program testing/evaluation facility authorized for

such purpose(s). Verification of such certification

shall be provided to DHH/OPH, subject to

acceptance by DHH/OPH of such verification, as

prerequisite to consideration of any individual

mechanical (residential) plant for permitting in Louisiana.

b. Evidence of acceptance by DHH/OPH of an

ANSI accredited testing/evaluation facility, for purpose of

testing/evaluation of individual mechanical (residential)

plant(s) for permitting in Louisiana shall be

demonstrated upon execution of an appropriate

Memorandum of Understanding (MOU), or other, similar

contractual instrument, subject to terms and conditions

as may be imposed by DHH/OPH―said MOU to be

between DHH/OPH and the testing/evaluation facility.

c. Successful completion of testing/evaluation of

an individual mechanical (residential) plant in

accordance with applicable provisions of this Code,

having been properly tested/evaluated and certified by

an appropriate facility, shall serve to allow the DHH/OPH

authorization of an individual mechanical (residential)

plant for permitting purposes in Louisiana for a period

not to exceed seven years from the date of such

DHH/OPH authorization, or until such time as an

appropriate revision to the prevailing testing/evaluation

standard for such purposes may become revised. Such

authorization of an individual mechanical (residential)

plant for permitting purposes in Louisiana shall be in the

form of a written license by DHH/OPH to a manufacturer

of such individual mechanical (residential) plant(s),

subject to compliance with applicable provisions of this

Code―such license to be valid for the specified period,

annually renewable, and suspendable/revocable by

DHH/OPH in accordance with license revocation

procedures as specified in §735.F.

2. Licensing

a. In addition to evidence of compliance of an

individual mechanical (residential) plant having been

properly tested/evaluated and certified by an

appropriate facility, certain additional requirements shall

serve as a basis for licensing by DHH/OPH of such

individual mechanical (residential) plant in Louisiana.

These additional requirements shall apply, as

appropriate, to the manufacturer and/or manufacturer

representative, agent, sub-manufacturer or other

associated entity, as appropriate, involved in the

manufacture, marketing, sale, installation and/or

maintenance of such (any) individual mechanical

(residential) plant(s) in Louisiana. Further, with respect to

the testing/evaluation facility which may have certified

the individual mechanical plants being in compliance

with the testing/evaluation standard contained herein,

certain additional requirements, for licensing

purposes, shall apply.

b. These additional requirements are

specified as follows.

i. Testing/Evaluation Facility

Responsibilities

(a). In addition to providing

testing/evaluation services with respect to

individual mechanical (residential) plants scheduled

for manufacture, marketing, sale, installation and

maintenance in Louisiana, the testing/evaluation

facility shall also serve to provide oversight liaison

services both to the manufacturer of the individual

mechanical (residential) plant, as well as to DHH/

OPH. However, DHH/OPH communication with the

testing facility will be at the OPH Program Manager

level, or higher. While it is recognized that the

testing/evaluation facility may exercise its fiduciary

right to exact such fees or other reimbursement

costs as appropriate from a manufacturer (client),

under no circumstances may the testing/evaluation

facility exact such fees or other reimbursement

costs from DHH/OPH in order to compensate for

any of these regulatory requirements. Accordingly,

the following requirements shall be included in the

MOU.

(b). It shall be required that all individual

mechanical (residential) plant manufacturers will be

inspected annually by the testing/evaluation facility

having certified the related individual mechanical

(residential) plant and that DHH/OPH shall be, upon

request, furnished with copies of all reports of such

inspections, which shall include at a minimum the

verification (or reverification) of all "forms" used in

the manufacture (or sub-manufacture) of individual

mechanical (residential) plants.

(c). It shall be required that a

representative number, up to 4 but in, no case more

than 10 percent, of all manufacturers authorized

sub-manufacturers of individual mechanical

(residential) plants will be inspected annually by the

testing/evaluation facility having certified the

related individual mechanical (residential) plant and

that a report shall be retained by the

testing/evaluation facility and shall, upon request by

DHH/OPH, make such information available to

DHH/OPH, which shall include at a minimum the

verification of service records for all related

individual mechanical (residential) plant installations and

availability of stand-by parts.

(d). It shall be required that a representative

number of installations in Louisiana, but in no case less

than 10, of all individual mechanical (residential) plants

manufactured by manufacturers and their respective

sub-manufacturers will be inspected annually by the

testing/evaluation facility having certified the related

individual mechanical (residential) plant and that a

report shall be retained by the testing/evaluation facility

and shall, upon request by DHH/OPH, make such

information available to DHH/OPH, which shall include at

a minimum the verification (or re-verification) that

individual mechanical (residential) plants and their

respective installation(s) are in conformity with the plans

and specifications as are reflected in the

testing/evaluation report which was approved for the

related individual mechanical (residential) plant.

(e). It shall be required that copies of all

inspection/audit reports conducted by a

testing/evaluation facility with regard to a client-related

manufacturer (or sub-manufacturer) of individual

mechanical (residential) plants will be retained by the

testing/evaluation facility and shall, upon request by

DHH/OPH, make such information available to DHH/OPH

upon completion of said report(s).

(f). It shall be required that copies of all

reports of non-compliance and/or reports of

complaint(s) investigations by a testing/ evaluation

facility with respect to a client-related manufacturer (or

sub-manufacturer) of individual mechanical (residential)

plant(s) will be retained by the testing/evaluation facility

and shall, upon request by DHH/OPH, make such

information available to DHH/OPH upon completion of

said report(s).

(g). It shall be required that any

modification(s) to an individual mechanical (residential)

plant, once certified by an ANSI accredited

testing/evaluation facility, shall be subject to re-

evaluation by the testing/evaluation facility and that

written acceptance of the change by the ANSI accredited

testing/evaluation facility shall be received by the

manufacturer prior to incorporating the change; this

information also to be transmitted to DHH/OPH.

(h). In the event that the original

testing/evaluation facility no longer conducts

testings/evaluations and certifications of individual

mechanical (residential) plants for a specific

manufacturer, it will be the responsibility of the

testing/evaluation facility to insure an orderly

transfer of the documentation supporting

certification to the manufacturer for transmittal to

another ANSI accredited testing/evaluation facility

at the manufacturers choice.